(Click here to see more "Full Site")

| Hannan Skin Packaging: 420T-24X30 |

$10,500 |

|

|

THE 420 T SERIES

A full automatic cycle machine with full manual override controls.

User friendly operation allows for high production or simple one-of-a-kind

or test packaging. The high efficiency oven provides the fastest cycle with

a minimum of energy. User friendly analog controls eliminate any need to

access computers or programs.

Features:

Pressure gauge indicates the proper air pressure for operation.

Vacuum gauge indicates the amount of vacuum being developed during the

cycle.

Vacuum range control regulates the exact amount of vacuum needed for

the job.

Independent heat and vacuum controls assure precise, consistent cycles.

Production monitor automatically keeps track of production rates (push

button reset)

Indicator lights register all functions.

Functional layout, with analog controls, allows easy operation without

the need for entry codes or programming.

Recessed, yet readily accessible instrument panel aids in quick setup

and consistent cycles.

Options

| Accessory work table |

2 Roll film carrier |

|

| Hot wire cut-off |

Varible Heat Control |

|

| Internal air compressor |

Special electrics |

|

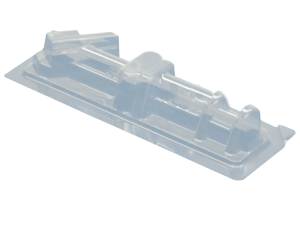

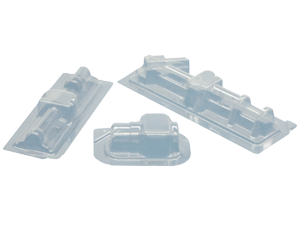

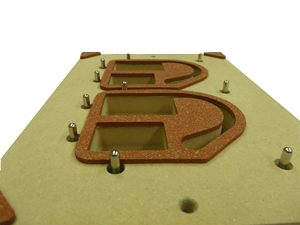

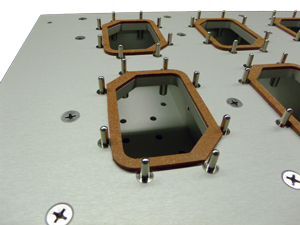

3D Packaging - "A 3D Sensory Decision"

The new 3D package allows consumers to view and touch the packaged products in retail spaces by viewing and touching. A 3D package, is the future of visual packaging.

Skin Packaging encourages the consumer to connect with the product by amplifying the sensory qualities of products in retail spaces.

Holding a 3D packaged product can create a sense of psychological ownership, driving a "Must-Have" purchase decisions.

About Packaging Terminology

The terms "Skin Packaging" and "Blister Sealing" refer to very specific

forms of packaging.

Quite often terms for other forms of packaging are used to refer to "skin

packaging" and "blister packaging".

Examples of these terms are "shrink packaging", "shrink wrap" , "shrink

pack", "stretch pack", stretch wrapping", "vacuum packaging", "vacuum pack",

"vacuum sealing", "bubble wrap", "bubble pack", "clam shell", "blister box",

and "clam pack"